Home ❯ Case Studies ❯ Harcourt House, London

Harcourt House, London

Harcourt House, London

Project |

Harcourt House |

Project type |

Residential |

Project location |

London, UK |

Client |

Ant Yapi UK |

Project Size |

5,478m2 |

Heating system |

Underfloor and Wall Heating |

System specifications |

|

The Challenge

Originally developed as a residential mansion block in 1907 before being converted into offices, the Edwardian Grade II listed Harcourt House is undergoing a major redevelopment to transform it into 25 luxury apartments and penthouses. Though technically a refurbishment project, large areas of the development were newly constructed within the existing structure. Warmup worked with the main contractor to provide the heating solution for both the refurbished and new build areas.

The Solution

With over 5000 sqm of floor space to radiantly heat, a combination of hydronic systems was decided upon to provide the most efficient heating solution. Much of the existing floorspace to be heated utilised a joisted batten floor construction so we opted to use the Tectora Hydronic System which is specifically designed for this subfloor type. In the new build areas, we commissioned the tried and tested Clypso System which offers ease of installation within a screeded subfloor.

Alongside floor heating, our StickyMat 360 Wall Heating System was installed to heat the bathrooms throughout the project. All heating systems are controlled with a Building Management System.

The Result

Marrying classic British architecture with a contemporary heating solution, Warmup’s floor and wall heating systems will provide a lifetime of automatic, energy-efficient warmth to the new residents of this premier London building.

Product information

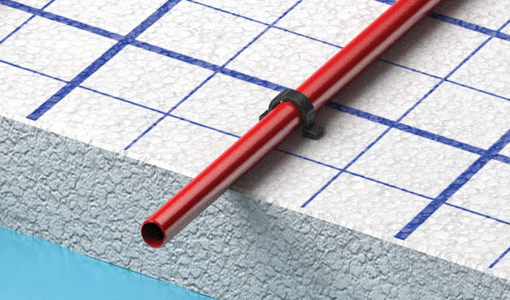

Clypso System

Tectora joisted floor system

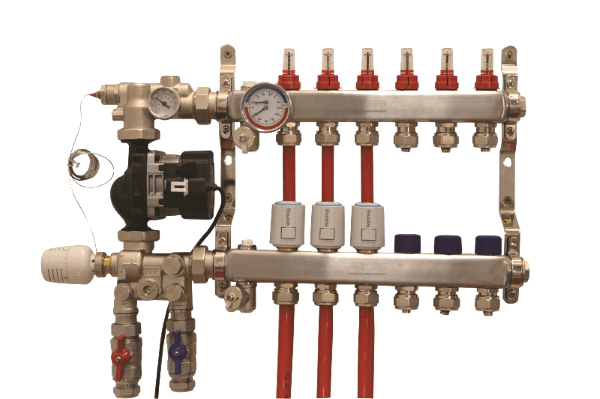

Manifold

Technical Information

The Clypso system uses plastic clips to secure the underfloor heating pipe to laminated insulation panels. The panels are constructed from either PIR (polyisocyanurate) or expanded polystyrene insulation with a fabric reinforced foil laminated to their surface. The foil on each panel comes with two flaps, for taping to the adjoining panel, thereby increasing water resistance and separating the insulation layer from the wet screed.